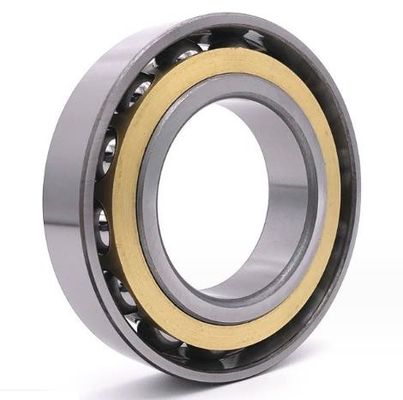

In today's rapidly developing industrial automation, the reliability of lubrication systems has become a core factor determining equipment lifespan and production efficiency. SKF, with a century of bearing technology accumulation, has launched lubrication solutions covering the entire life cycle, providing one-stop technical empowerment for enterprises from design optimization to intelligent operation and maintenance.

Precise design: customized lubrication solutions break through industry bottlenecks

SKF designs exclusive lubrication systems for different working conditions. Taking the electric spindle as an example, its oil vapor lubrication technology reduces the bearing wear rate by 62% and extends the lubrication cycle from 500 hours to 1500 hours through dynamic monitoring and precise oil supply. After being applied in a precision manufacturing enterprise, the annual maintenance cost of a single equipment has been reduced by 40%, and the production capacity has been increased by 15%. This technological breakthrough not only solves the problem of "excessive/insufficient" in traditional lubrication, but also controls the spindle temperature gradient within 5 ℃ through dual channel cooling technology, ensuring the stability of ceramic bearings under heavy cutting conditions.

Intelligent operation and maintenance: data-driven predictive maintenance

The SKF lubrication system is equipped with advanced sensors and IoT technology to achieve real-time monitoring and intelligent decision-making of lubrication status. The Lubrication Guard (RHWS) solution can perform comprehensive status monitoring of lubrication media, equipment, and pipelines, and provide early warning of potential faults through cloud data analysis. After a certain coal mining enterprise adopted an intelligent lubrication device, the oil injection efficiency increased by 300%, and the equipment failure rate decreased by 70%, completely solving the problems of long cycle and large waste of manual oil injection.

Green Transformation: The Sustainable Value of Energy Conservation and Emission Reduction

SKF lubrication system reduces energy consumption and lubricant waste by optimizing the lubrication process. Taking a certain automotive parts enterprise as an example, after applying the SKF solution, the annual carbon emissions of a single equipment were reduced by 20 tons, which meets the strict requirements of green manufacturing in the Industry 4.0 era.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!