Product Description:

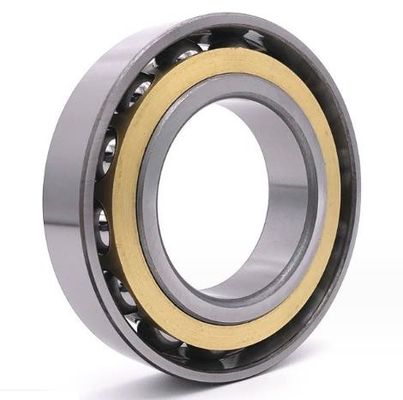

The Cylindrical Roller Bearing is a pivotal component in the realm of mechanical engineering and machinery, designed to withstand high radial loads while maintaining high-speed capabilities. This robust bearing is an essential element for a wide range of applications, including but not limited to, automotive, industrial, and aerospace industries. With a focus on versatility and performance, this product ensures that machinery operates smoothly and efficiently.

The TP type thrust bearings are cost efficient and several sizes are readily available from inventory. They comprise two hardened and ground steel washers, a machined brass cage and steel rollers.

One of the standout features of this Cylindrical Roller Bearing is the variety of vibration levels it can be supplied in. Available in V1, V2, V3, and V4 categories, it caters to different requirements for precision and smoothness in operation. The V1 and V2 levels are suitable for general applications where standard vibration levels are acceptable. In contrast, the V3 and V4 levels are designed for applications requiring higher precision and reduced vibration, making them ideal for more sensitive or high-speed applications.

The bearing’s cage is another critical attribute that dictates its performance and suitability for certain applications. With options for a Steel Cage, Brass Cage, and Nylon Cage, this product can be tailored to specific operational needs. The Steel Cage is highly durable and capable of withstanding high temperatures, making it suitable for heavy-duty applications. The Brass Cage offers excellent resistance to corrosion and reduced friction, which is advantageous in high-speed applications. The Nylon Cage, being lightweight and having a lower coefficient of friction, contributes to the bearing's overall efficiency, particularly in applications where noise reduction is crucial.

With a sealed Seals Type design, this Cylindrical Roller Bearing facilitates ease of lubrication and maintenance. The sealed ends allow for lubricants to be applied directly to the rolling elements and raceways, ensuring that friction and wear are minimized over extended periods of operation. This feature also contributes to the bearing's capacity to operate at higher temperatures as it allows for better dissipation of heat generated during use.

The bearing seamlessly integrates with other high-quality bearing solutions such as TNT Combined Needle Roller Bearings, which are known for their compact design and high load-carrying capacity. It also complements the FAG Spherical Roller Bearing range, renowned for accommodating misalignment and dealing with heavy loads. Its compatibility with Single Row cylindrical roller bearings makes it versatile for use in configurations where radial load capacity and high-speed operation are required.

In summary, this Cylindrical Roller Bearing is a high-quality product that offers adaptability, efficiency, and performance. Whether it is for general-purpose machinery or specialized equipment, this bearing is engineered to meet the demands of modern applications. Its thoughtful design and construction, with options for different vibration levels, cage materials, and lubrication types, make it an indispensable component for anyone looking to achieve reliable and efficient machinery operation.

Features:

- Product Name: Cylindrical Roller Bearing

- Seals Type: Sealed

- Lubrication: Oil Lubrication, Grease Lubrication

- Precision Level: P6, P5, P4, P2

- Width: 114.3mm

- Material: Chrome Steel, Carbon Steel

- Keywords:

- Single Row cylindrical roller bearings

- SKF Conveyor Roller Bearing Housing

- TIMKEN Cylindrical Roller Bearing

Technical Parameters:

| Parameter |

Specification |

| Width |

11mm |

| Vibration Level |

V1, V2, V3, V4 |

| Seals Type |

Sealed |

| Clearance |

C5, C4, C3, C0 |

| Service |

agent |

| Outer Diameter |

635mm |

| Separable |

Yes |

| Cage |

Steel Cage, Brass Cage, Nylon Cage |

| Weight |

130kg |

| Material |

Chrome Steel, Carbon Steel |

Applications:

The cylindrical roller bearing is an essential component used in a variety of industrial and mechanical applications. Our range of cylindrical roller bearings, including the Four Row cylindrical roller bearings, TIMKEN Cylindrical Roller Bearing, and TNT Combined Needle Roller Bearings, are designed to meet the rigorous demands of heavy-duty operations. These bearings are manufactured under well-known brand names such as INA/FAG / LYC, ensuring reliability and performance.

Originating from China and backed by quality certifications such as ISO9001-2015, SGS, BV, CE, and IAF, our cylindrical roller bearings are a testament to superior craftsmanship. With a minimum order quantity of just 10 units and negotiable pricing, these bearings are both accessible and affordable. They come with independent packing, ensuring they reach you in impeccable condition. Delivery is swift, with an estimated time frame of about 5 to 8 days from the order, and payment is conveniently processed via T/T in advance.

Our cylindrical roller bearings are versatile and can be used in scenarios where high radial load capacity is crucial. They are separable, which facilitates easy mounting and dismounting. The variety of cages available, such as steel, brass, and nylon, allows for customization based on application requirements. Lubrication options include both oil and grease, providing the flexibility needed for different operating environments. We offer a wide range of precision levels (P6, P5, P4, P2) and vibration levels (V1, V2, V3, V4) to ensure optimal performance in various settings.

Application occasions for these cylindrical roller bearings are diverse. They are ideal for heavy industries, such as steel and aluminum production, where the Four Row cylindrical roller bearings provide exceptional radial load capacity and rigidity. Additionally, the TIMKEN Cylindrical Roller Bearing is well-suited for applications in mining and construction equipment, offering high durability and resistance to impact loads. TNT Combined Needle Roller Bearings are often utilized in automotive and aerospace applications, where a compact and lightweight design is critical. With a supply ability of 7.5KKPCS/Month, our bearings support the needs of both large-scale projects and specialized machinery.

In summary, whether you're looking to outfit heavy machinery or require precision bearings for high-speed applications, our comprehensive lineup of cylindrical roller bearings is engineered to exceed expectations. We deliver not just a product but a promise of quality, efficiency, and reliability.

Customization:

Brand Name: INA/FAG / LYC

Place of Origin: China

Certification: ISO9001-2015/SGS/BV/CE/IAF

Minimum Order Quantity: 10

Price: Negotiable

Packaging Details: Independent packing

Delivery Time: about 5~8 days

Payment Terms: T/T in advance

Supply Ability: 7.5KKPCS/Month

Lubrication: Oil Lubrication, Grease Lubrication

Clearance: C5, C4, C3, C0

Seals Type: Sealed

Precision Level: P6, P5, P4, P2

Number of Row: Two Row

Our HRB Cylindrical Roller Bearing comes with various customization options to meet your specific requirements. Whether you need Single Row cylindrical roller bearings for high-speed applications or Four Row cylindrical roller bearings for heavy load carrying capacity, we offer premium quality bearings that ensure durability and performance.

Support and Services:

Our Cylindrical Roller Bearing product is designed with precision engineering to ensure high radial load capacity and performance. To ensure customer satisfaction and the longevity of your bearing, we offer comprehensive technical support and services.

Technical Support:

1. Installation Guidance - Our team of experts provides step-by-step instructions and best practices for installing your Cylindrical Roller Bearings to ensure optimal performance and prevent early failure.

2. Troubleshooting - In case of any operational issues, our technical support team is ready to assist with troubleshooting steps to identify and solve the problem effectively.

3. Maintenance Tips - We provide detailed maintenance guidelines to help you extend the life of your bearings, including lubrication schedules, inspection tips, and cleaning recommendations.

4. Technical Documentation - Access to comprehensive technical documents, including data sheets, material specifications, and CAD models, is available to support your engineering needs.

Services:

1. Warranty Service - Our Cylindrical Roller Bearings come with a warranty, and we offer repair or replacement services for any product that fails due to manufacturing defects within the warranty period.

2. Product Training - We offer training sessions on the proper handling, installation, and maintenance of our bearings to ensure your team is well-equipped to manage the product.

3. Custom Solutions - If you have specific application needs, our engineering team can work with you to develop custom bearing solutions tailored to your requirements.

4. After-Sales Support - Our commitment to your satisfaction continues after the purchase, with responsive after-sales support to answer any queries or provide additional assistance as needed.

FAQ:

Q1: What brand names are available for your Cylindrical Roller Bearings?

A1: We offer a variety of brand names for our Cylindrical Roller Bearings, including INA/FAG / LYC.

Q2: Where are your Cylindrical Roller Bearings manufactured?

A2: Our Cylindrical Roller Bearings are manufactured in China.

Q3: Do your Cylindrical Roller Bearings come with any certification?

A3: Yes, our Cylindrical Roller Bearings are certified with ISO9001-2015, SGS, BV, CE, and IAF certifications, ensuring high quality and reliability.

Q4: What is the minimum order quantity for Cylindrical Roller Bearings?

A4: The minimum order quantity for our Cylindrical Roller Bearings is 10 units.

Q5: How are the Cylindrical Roller Bearings packaged?

A5: Our Cylindrical Roller Bearings come with independent packing, ensuring they are well-protected during transport.

Q6: How long does it take to deliver Cylindrical Roller Bearings after placing an order?

A6: The delivery time for our Cylindrical Roller Bearings is about 5 to 8 days after the placement of an order.

Q7: What are the payment terms for purchasing Cylindrical Roller Bearings?

A7: The payment terms for our Cylindrical Roller Bearings are T/T in advance.

Q8: What is the supply ability for your Cylindrical Roller Bearings?

A8: We have a supply ability of 7.5KKPCS per month for our Cylindrical Roller Bearings.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!